KENTAI

เครื่องเจียรใบเลื่อยกึ่งอัตโนมัติ

Machine Features:

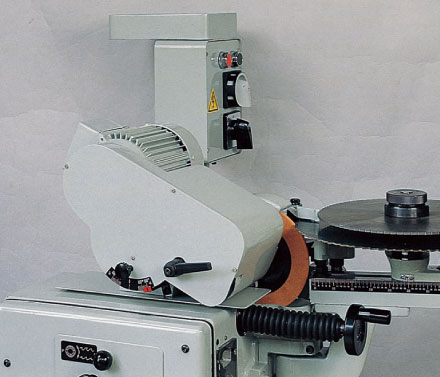

SG-1

Semi-Automatic Saw Grinding Machine is suitable for HSS, Tungsten Carbide, opening for Friction Saw, Grinding, Chamfering, Pipe and pipe product manufacturing. The machine structure is strong and stable, with a service life of several decades, saving maintenance or replacement costs. Sufficient stock with consumptive parts and can be shipped for customer replacement at any time without wasting time on standby.

- All castings are made of spherical graphite cast iron (FCD-45) to ensure accuracy and increase wear resistance.

- Simply shift between Straight tooth (A type) and Curved tooth (B type).

- The thickness of different saw blades can be accurately adjusted via the gauge.

- The feeding speed is adjusted by stepless speed, which can quickly adjust the required speed with the change of the tooth pitch.

- Alternate high teeth(C Type) and low teeth(Copperstone) shall be accomplished by one pass. The teeth height difference is variable and read out from indicating meter, thus you got a perfect sharpening result.

- Teeth chamfering is easily made without replacing grinding wheel, only swings upward or downward to aim the indication meter."

Mechanism

- All cast-iron components are made from DUCTILE IRON (FCD-45), wear resisting to assure prec

Speed

- Driving speed change by a stepless adjusting device, regard to change speed for different blade pitch promptly.

High-Low Tooth

- Alternate high/low teeth shall be accomplished by one pass. The teeth height difference is variable and read out from indicating meter, thus you got a perfect sharpening result.

Tooth Profile

- Simply shift between Straight tooth (A type) and Curved tooth (B type).

Saw Blade

- During saw blade install, the blade thickness setting is quick and accurate according an indicating meter.

Chamfer

- Teeth chamfering is easily made without need to replace grinding wheel, only swings upward or downward to aim the indication plate.

- Teeth chamfering is easily made without need to replace grinding wheel, only swings upward or downward to aim the indication plate.

Teeth Chamfering

Grinding head swing up-wards, grinding off the up-ward chamfer

Grinding head swing down-wards, grinding off the down-ward chamfer

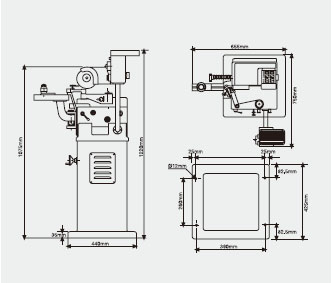

Machine Specifications:

| Instruction / Model. | SG-1 |

|---|---|

| Saw blade diameter | Ø50 ~ Ø450 mm |

| Pitch range | Max. 25 mm |

| Depth of teeth | Max. 8 mm |

| Range of cutting angle | -5 ° ~ 30 ° |

| Feeding speed | 45~180teeth/minute |

| Thickness of saw blade | Max. 8 mm |

| Grinding wheel diameter | Ø75 ~ Ø150 mm |

| Wheel inner diameter | Ø25 mm |

| Grinding wheel speed | 4200 rpm |

| Grinding wheel motor | 0.55 kw 2p |

| Driving motor | 0.37 kw 2p / 4p |

| Dust suction motor | 0.37kw2p(optionalacc.) |

| Net weight | 130 kgs |

| Gross weight of packing | 180 kgs |

| Packing size (W x H x D) | 970 x 1460 x 870 mm |

* The specifications subject to change without prior notice.